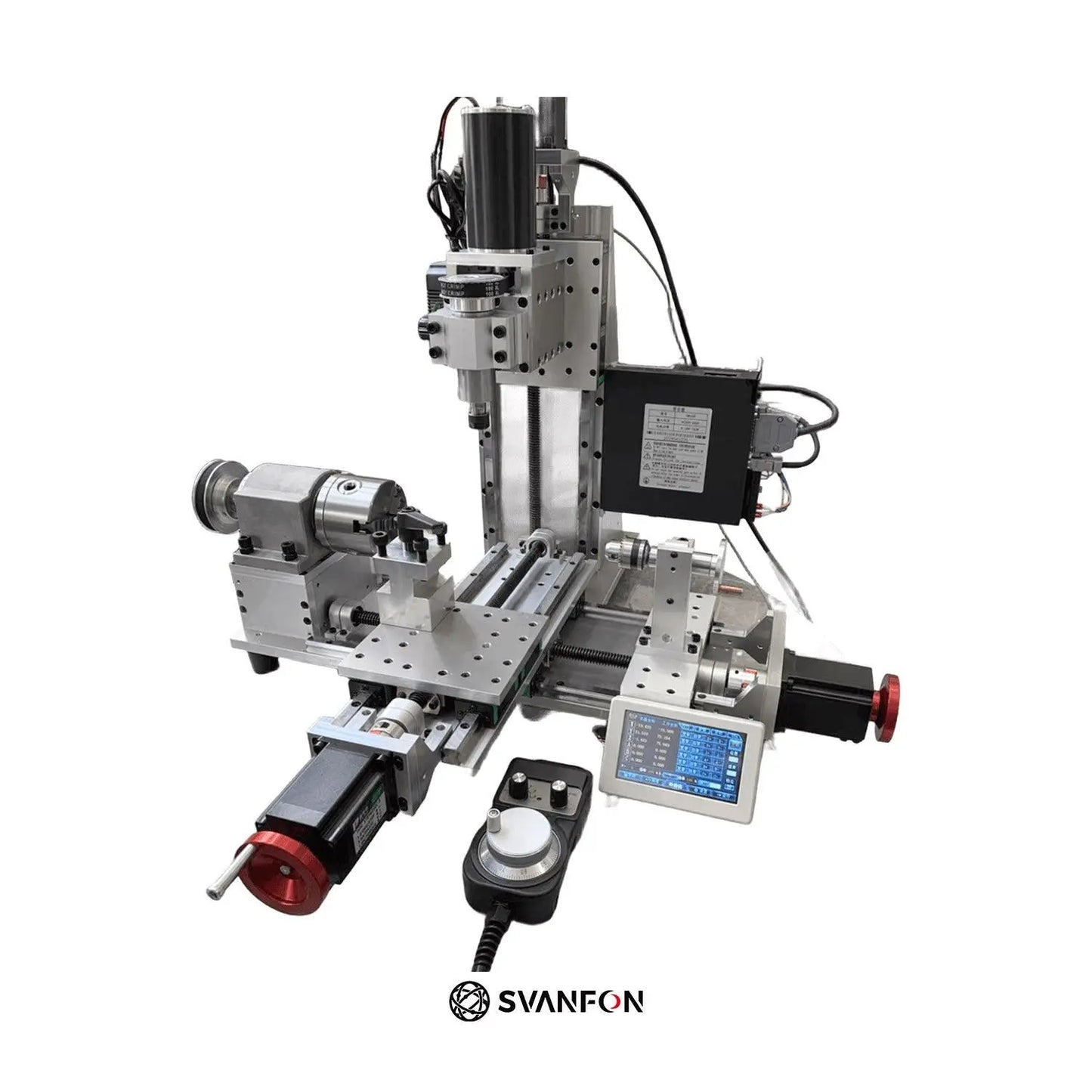

Mini Lathe–Mill–Drill Combo Machine – 3-in-1 Metalworking Centre

Mini Lathe–Mill–Drill Combo Machine – 3-in-1 Metalworking Centre

SvanFon

Não foi possível carregar a disponibilidade de retirada.

Description

Mini Lathe-Milling Machine Instruction Manual

Product Overview

The mini lathe-milling machine is a desktop-level multifunctional processing equipment with high portability and flexibility, suitable for various scenarios.

Feature

1.Powerful processing ability

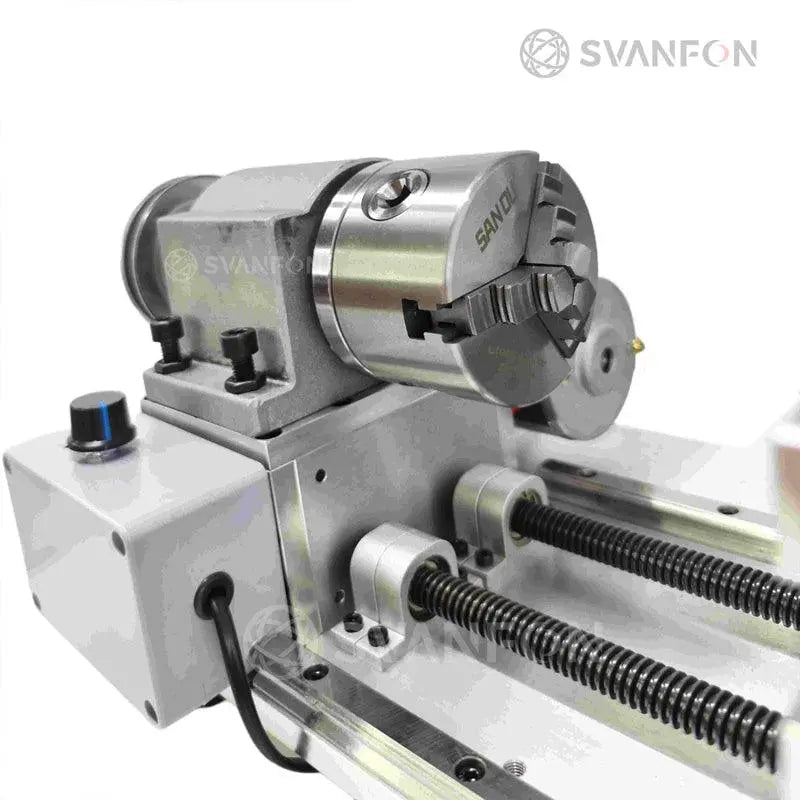

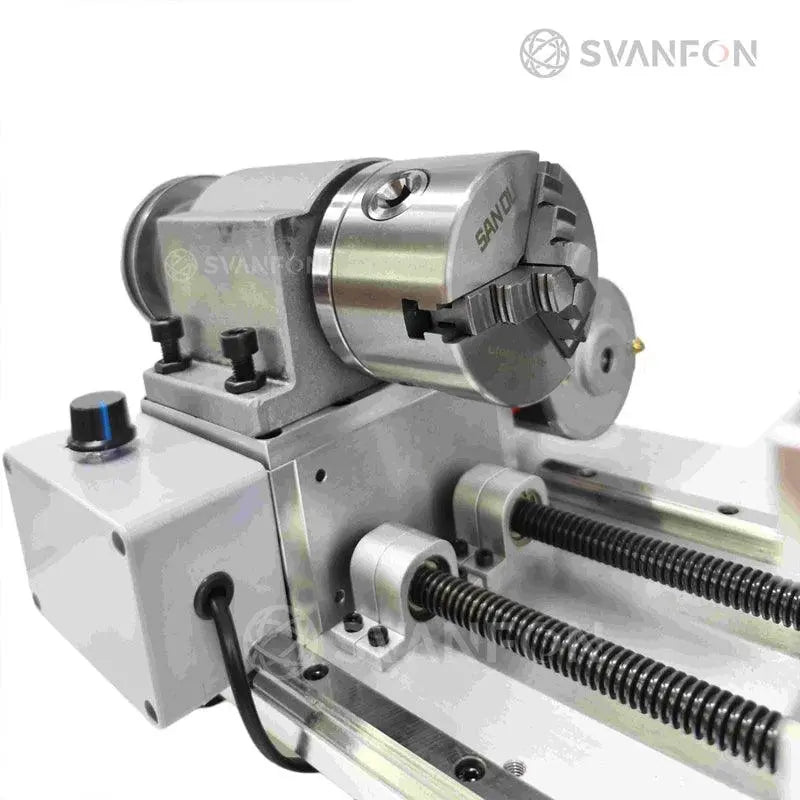

- Lathe: Equipped with a 100W motor and an 80 manual three-jaw chuck. The maximum processing diameter is 60mm and the length is 160mm. It can process various materials such as copper, iron, aluminum, 304 stainless steel, and 45 steel.

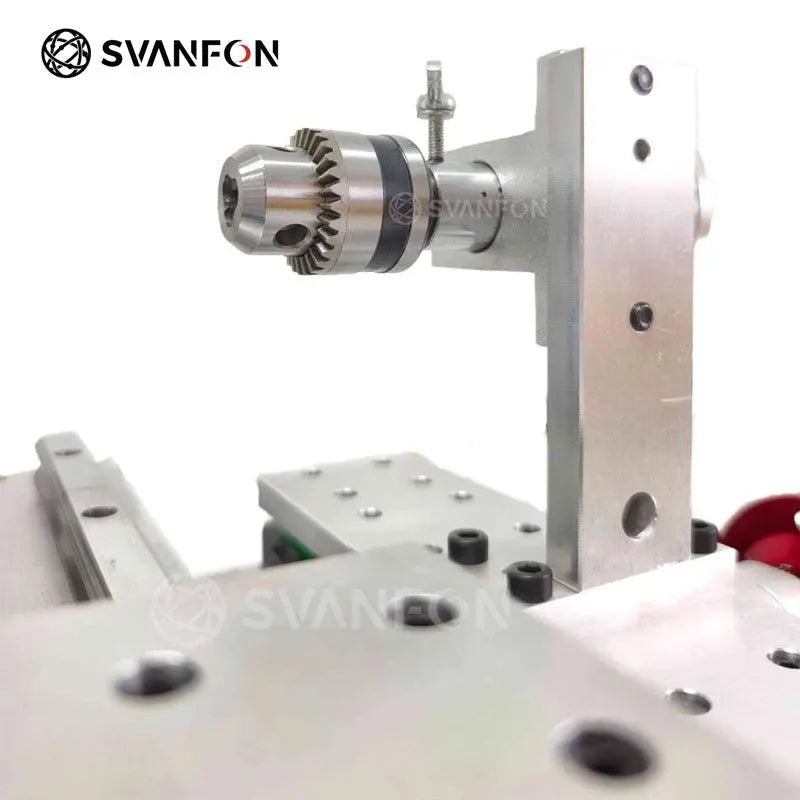

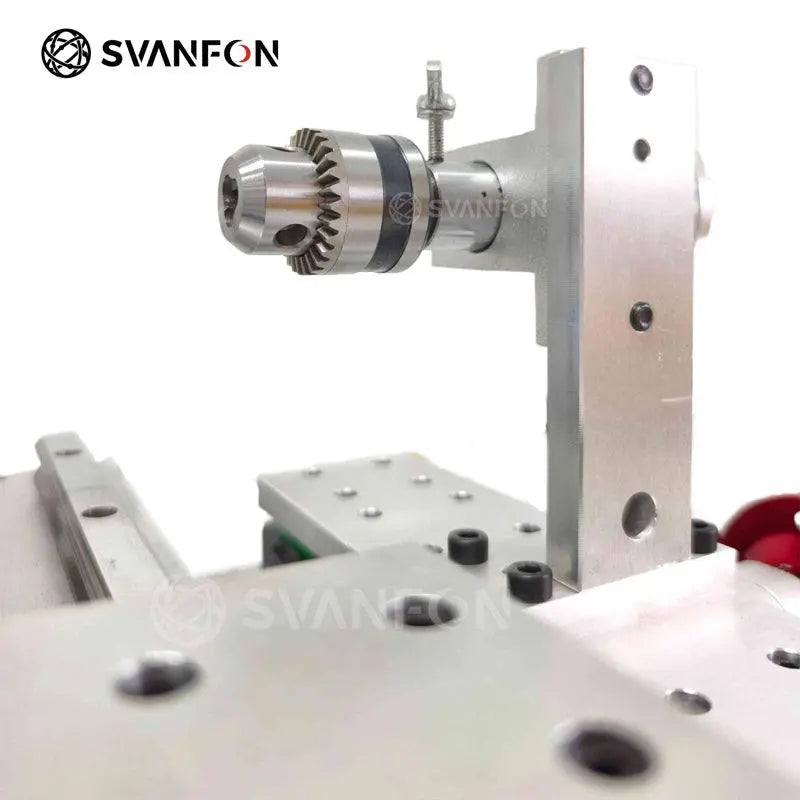

- Milling machine: Comes with a 100W motor and can process copper and aluminum.

- Capable of performing various processing operations such as turning, milling, and drilling to meet different processing needs.

2.Up grad ability

- Motor upgrade: Can be upgraded to a 200W or 350W high-torque motor to enhance processing ability.

- Whole machine upgrade: The entire machine can be upgraded to a CNC system to achieve high-precision processing operations such as threading and milling threads.

3.High play ability

Inspires users' creativity and allows for personalized processing and transformation according to different needs.

III. Product Parameters

- Product size: 610/610/510 mm (Length Width Height), weight: 33KG.

- Packaging size: Carton 550/450/200mm (Length Width Height), weight: 35KG (loose parts packaging).

- Lathe spindle motor power: 100W, input voltage AC 220V, maximum speed 4500 rpm±5%.

- Milling machine spindle motor power: 100W, input voltage AC 220V, maximum speed 4500 rpm±5%.

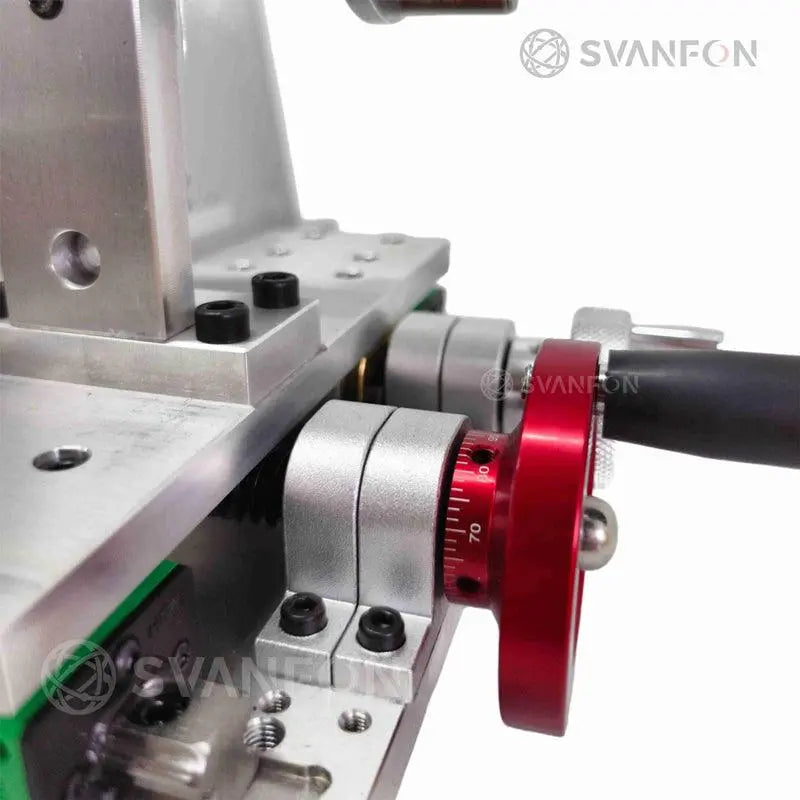

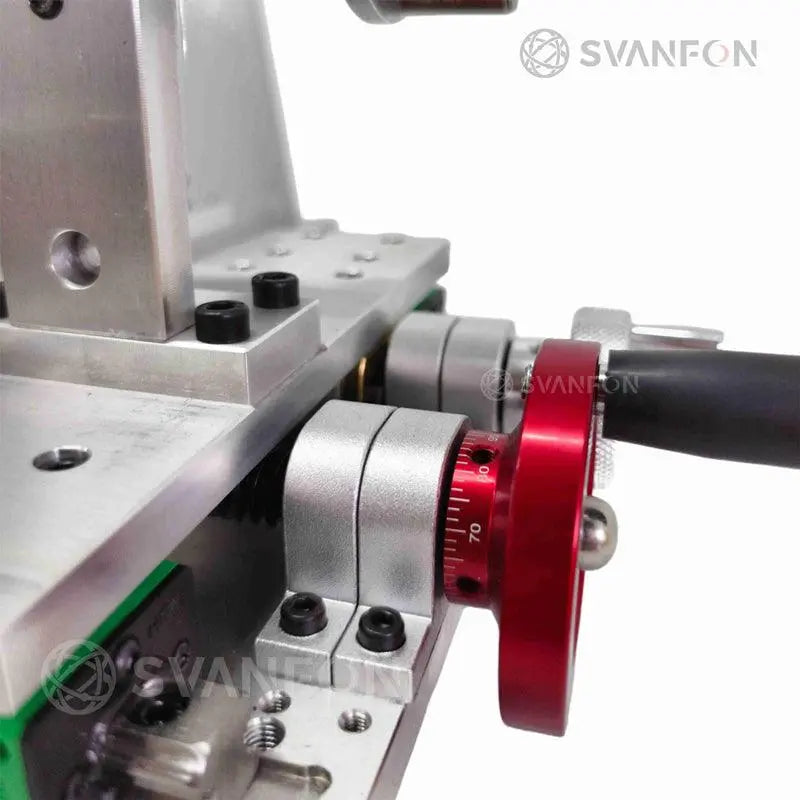

- XYZ travel: 140mm.

- Tail stock: Chuck size ≤4mm, stroke of chuck: 35mm, tail stock stroke: 160mm. (The chuck and tail stock can operate independently.)

- Lathe spindle: Standard with an 80 chuck. The spindle through hole is 16mm. The maximum speed is 2000rpm (adjustable speed), and the reduction ratio is 2.25.

- Turning length: ≤160mm.

- Milling machine spindle: ER11 powerless spindle. Tool size ∅1~7mm. The maximum speed is 2600rpm (adjustable speed), and the reduction ratio is 1.67.

350W vs 680W Rotor Comparison

Feature |

350W Rotor |

680W Rotor |

|---|

Fan Diameter |

Standard |

10mm larger with 4 more blades (better heat dissipation, longer working time) |

Windings & Wire Thickness |

Standard |

More windings, thicker wire (higher efficiency, greater torque) |

Commutator Size |

Standard |

Twice the size (more durable, stable speed, less sparking) |

Fixing Inserts |

Not included |

Added (prevents wire dislodging at high speeds) |

Upgrade to CNC

After upgrading to the CNC system, functions such as automatic feeding, threading, and milling threads can be realized, inspiring users' creativity and improving the performance of the machine. This equipment is a highly playable DIY device.

Parameters of CNC version

- Product size, length, width and height 710x710x610

- Product weight. 43kg

- Power-speed of XYZ axis. Maximum moving speed 3000. 3 meters per minute

- Lathe spindle power. Standard 350w DC motor, 750w servo threading

- Milling machine spindle power, 350w DC motor

- Machining on a lathe with a diameter of 60mm and a length of 120mm.

Milling machine: 140mm x 120mm. Z-axis travel: 140mm. - 7-inch wired electronic screen, English operation interface.

- Electronic handwheel

Other options:Lathe tools, milling cutters, chucks, and centers.

Transportation Method

- In the form of parts (default way, comes with video assembly tutorials).

- Assembled finished product way (not recommended for export countries as it requires a relatively high cost).

Share

Although the assembly was exhausting, I was pleasantly surprised to see the finished product.